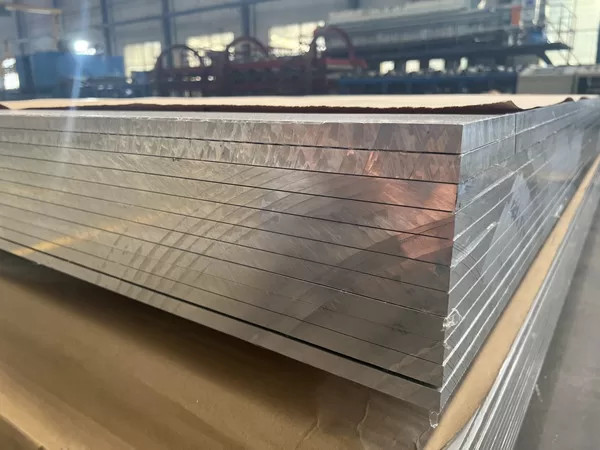

6061 Aluminium Plate

- Home

- 6061 Aluminium Plate

6061 aluminium plate is a heat-treatable alloy with good formability, weldability, machinability, and moderate strength, which can still maintain good strength after annealing. The main alloying elements of 6061 aluminium plate are magnesium and silicon, and form Mg2Si phase. It has high strength. It is commonly used in the field of construction, and there are many other uses, you can choose after a detailed understanding of the following application.

Specification of 6011 aluminum plate

6011 aluminium plate | temper | Thickness(mm) | Width(mm) |

| O,H14,H16,H18,H24,H26,H116 | 0.2-100 | 10-2700 |

Advantages of 6061 aluminium

- High strength: 6061 aluminium plate offers impressive strength properties, so it more suitable for structural applications. It can withstand heavy loads. And it is often used in scenarios where durability is crucial.

- Corrosion Resistance: This alloy is highly resistant to corrosion, so it is idea for outdoor and marine applications. It does not rust or corrode easily, ensuring the longevity of the components made from it.

- Lightweight: Its low density gives it an excellent strength-to-weight ratio. This makes it valuable in applications where reducing weight is essential, such as aerospace and automotive industries.

- Weldability: Easily welded using a variety of techniques. This makes it a versatile material for constructing complex structures and assemblies

- Machinability: Its good machinability ensures that manufacturers can easily shape and machine 6061 aluminum plates into desired forms, reducing manufacturing time and costs.

- Excellent heat dissipation: Its ability to dissipate heat efficiently makes it suitable for applications where temperature management is important, such as electronic enclosures and heat sinks.

Application of 6061 aluminium plate

- Aerospace: Aerospace aluminum can make many kinds of products.Such asaircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

- Transportation:transportation aluminum used in automobiles, subway vehicles, railway buses, high-speed passenger cars, car structure parts, car doors and windows, shelves, automobile engine parts, air conditioners, radiators, car body panels, wheels and ship materials.

- Construction field:

①Architectural decoration :Aluminum alloy for architectural decoration because of its good corrosion resistance, sufficient strength, excellent process performance and welding performance.

②Building frames:It has a widely usage in building frames, doors and windows, ceiling, decorative surfaces and so on. Such as all kinds of building doors and windows, curtain wall with aluminum profiles, aluminum curtain wall panels, pressure plate, pattern plate, color coated aluminum plate.

- Electronic appliances:Aluminum for electronic appliances has a wide range of use in various bus bars, wires, conductors, electrical components, refrigerators, air condition, cable and other fields.

- Packaging:Aluminum can materials has a certain use in metal packaging materials in the form of sheet and foil. And they are made into cans, caps, bottles, drums and packaging foils. It has a widely usage in beverage, food, cosmetics, pharmaceuticals, cigarettes, industrial products and other packaging.

- Printing: Printing aluminum is mainly used for the production of PS plate, aluminum based PS plate is a new type of material in the printing industry, automatic plate making and printingis the common usage.

Mechanics Performance of 6061 aluminum

- The ultimate tensile strength of 6061 is above 205MPa.

- Tensile yield strength 55.2MPa.

- The elastic coefficient is 68.9GPa.

- Ultimate bending strength 228MPa.

Heat treatment of 6011 aluminum plate

- Rapid annealing: heating temperature 350~410℃. With the different effective thickness of the material, the holding time is between 30~120min. Air-cooled or water-cooled.

- High temperature annealing: heating temperature 350~500℃. When the thickness of the finished product is ≥6mm, the holding time is 10~30min.And when it is <6mm, the heat will be thoroughly heated. The air is cold.

- Low temperature annealing: heating temperature 150~250℃.The holding time is 2~3h. Air or water cooling. Homogenization :570 degrees Celsius, held for 7 hours, air-cooled.