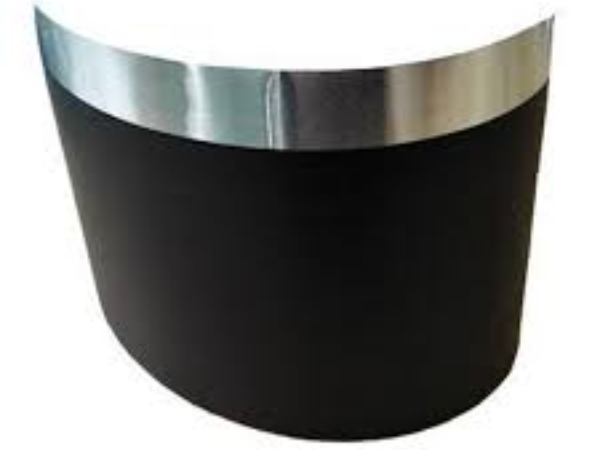

8021 aluminum foil has good covering power and strong moisture-proof and barrier capabilities, so it is often used in pharmaceutical packaging, food packaging and battery casings.

Product in detail

| Alloy | 8021 |

| Temper | H18, O, etc |

| Thickness | 0.006mm-0.2mm |

| Width | 20mm-1250mm |

| Color | silver |

| Inner core | alu core/Iron core |

| Core ID | 76mm, 152mm |

| Package | suspended wooden box packaging, floor wooden box packaging |

| MOQ | 5 tons |

Advantage

- Surface: Its surface is smooth, uniform in color, no spots, and good flatness.

- Barrier capacity: It has excellent moisture-proof properties, light-shielding properties and extremely high barrier capabilities.

- Mechanical behavior: It has mechanical properties such as burst resistance, puncture resistance, and tear resistance.

- Smell: It is non-toxic, odorless and hygienic.

- Good lamination: It can be laminated with plastic and paper and is not easy to fall off or delaminate.

- Excellent punching and puncture resistance: Its elongation rate can reach 13%-18%, and the cup height can reach 7.3mm.

Application

Alu alu pharmaceutical foil

Pharmaceutical foil is divided into two types: blister foil and alu alu foil. One side of the blister foil is plastic and the other side is aluminum foil. Alu alu foil has aluminum foil on both sides. Therefore, alu alu foil has higher requirements for sealing and elongation. It usually uses aluminum foil of 8021 and 8079 alloys.

Battery Soft pack foil

Compared with traditional batteries, batteries made of 8021 aluminum foil are lighter, thinner, have longer cycle life, good safety, high energy density, excellent power performance, and are environmentally friendly and pollution-free.

Label foil

8021 aluminum foil has the characteristics of cleanliness and hygiene, and can be made into integrated packaging materials with many other packaging materials. In addition, the surface printing effect of 8021 aluminum foil is better than other materials. Therefore, 8021 aluminum alloy is also commonly used in beer packaging.

The difference between 8011 aluminum foil and 8021 aluminum foil

8011 aluminum foil has higher strength, but its elongation and puncture resistance are lower than 8021 aluminum foil. Therefore, 8021 aluminum foil is relatively expensive and is mostly used in the packaging of soft aluminum-plastic films for lithium batteries and blister pharmaceuticals that require relatively high requirements. 8011 aluminum foil is widely used and can be used in many fields such as pharmaceutical packaging, food packaging, lunch box materials, tape foil, cable foil, milk cap materials, bottle cap materials, etc.

Production Process

The aluminum foil manufacturing process generally goes through casting, homogenization, surface treatment, hot rolling, cold rolling, foil rolling, cleaning, winding, annealing, and finally cutting.

Mechanical Properties

| Tensile strength(MPa) | Elongation(%) | Cupping test value(mm) |

| 90-110 | 13-18 | 6.0-7.5 |

Chemical Composition

| Si | Fe | Cu | Mn | Mg | Zn | Others | Al |

| 0.15 | 1.2-1.7 | 0.05 | 0.05 | 0.05 | 0.05 | 0.005 | remain |

Our service

- We will give you a professional reply in the shortest possible time.

- We can provide free samples for testing.

- We provide international Standard Seaworthy Packaging wooden pallets/Skids/Cases/Boxes.

- We strictly control quality.

- We have many professionals and technicians, more competitive prices and the best after-sales service than other companies.

- We can customize products according to customer requirements.

Company introduction

Henan Jurun new material Co., Ltd. is a company specializing in the production and sales of aluminum foil, plain aluminum sheet/coil, color coated aluminum sheet/coil, checkered plates and other aluminum products. Our company has set up a foreign trade office in Zhengzhou. Our factory is located in Huiguo Town Industrial Park, Gongyi City, covering an area of 80,000 square meters, with a current annual output of 50,000 tons and more than 500 employees. Our company uses advanced production equipment to ensure the high quality of its products. We have a core technical team that strictly controls and improves product quality to ensure production efficiency and product quality. At present, our products have passed ISO 9001 quality management system, SGS, etc and are sold all over the world.