Aluminium Honeycomb Core

- Home

- Aluminium Honeycomb Core

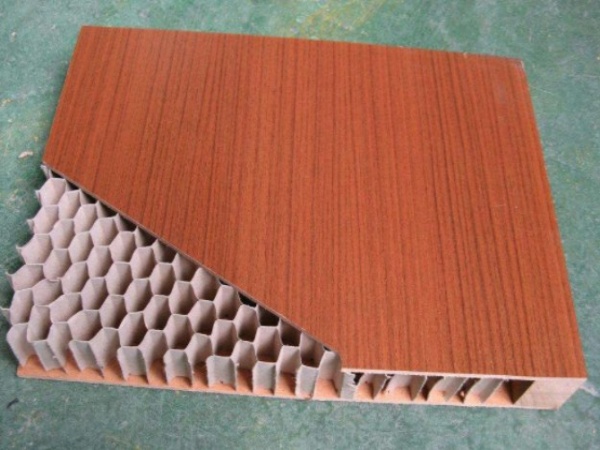

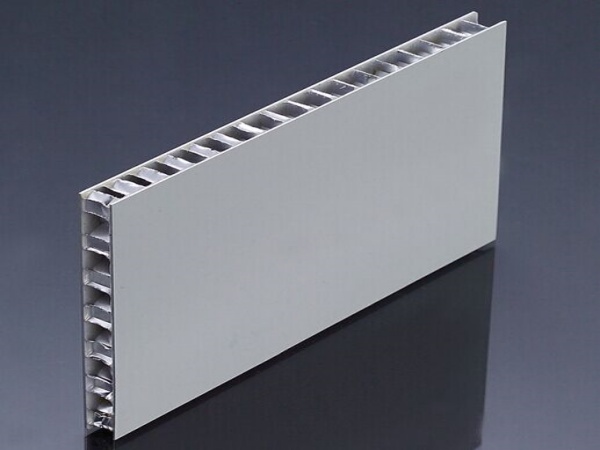

Aluminum honeycomb core is the intermediate material of aluminum honeycomb panel. In the past, aluminum honeycomb materials were widely used in aerospace and military fields. With the development of technology and growing needs of people, it begins to appear in our daily life.

Specification of Aluminum Honeycomb Core

Item | Aluminum Honeycomb Core |

Material | Aluminum metal alloy and aluminum foil |

Alloy | 3 series, 5 series etc |

Surface | Multiple hexagons on the surface |

Color | Metal color |

Advantages and Application of Aluminum Honeycomb Core

Advantages:

- Fire protection: Aluminum core is a non-combustible material.

- Moisture resistance: The surface of aluminum honeycomb material is treated by epoxy fluorocarbon, with strong corrosion resistance. No pinholes, cracks or bubbles after 48 hours of salt spray.

- Environmental protection:Honeycomb core is a pure aluminum products, does not volatilize any harmful gases to the human body, no radioactivity and can be fully recycled, 100% environmentally friendly products.

- Easy to remove and assemble without breaking the sheet: Because of its light weight and convenient transportation, it can be transported to different places and reused many times. This is other partition plate can not be compared.

- Sound insulation :As the sandwich between the honeycomb panel, the honeycomb core can effectively soundproof and reduce noise.

- High strength and good impact resistance.

Applications:

Aluminium honeycomb core provides more choices and convenience for people life. Making honeycomb aluminum panel is the main application of aluminium honeycomb core. Aluminum honeycomb panel is a sandwich panel which takes aluminum honeycomb core as the core.

- Aluminum honeycomb panel

- Aerospace

- Manned spaceflight

- Construction

- Railway construction

- Train

- Filtration

- Shielding

- Furniture industry

Common alloys and characteristics of Aluminum Honeycomb Core

3003

It has good performance of light weight, pretty comprehensive strength and so on. The alloy contains 97 percent aluminum, 1.5 percent manganese, and a small amount of iron and silicon. With good welding, contact resistance and formability, the strength is slightly higher than 1100 alloy, also known as aluminum-manganese alloy · Main application: sheet metal materials, building materials (curtain wall, shelter), ship materials.

5052

5052 core is commonly used in the fields of architecture, aviation, engineering, transport and energy. This aluminum alloy containing 96% aluminum, 2.2~2.8% magnesium, and a small amount, silicon, copper, manganese, etc., also known as aluminum-magnesium alloy, has good welding, resistance and formability, is a representative alloy of medium strength, its strength has usages in aerospace, ships, vehicles, building materials (ceilings, doors, sound walls).

How To Cut Aluminum Honeycomb Core?

As the application of aluminum honeycomb cores becomes wider, more and more manufacturers begin to produce honeycomb cores.

When cutting honeycomb core, we require special honeycomb cutting equipment. First of all, we need to choose instruments with high efficiency, high product precision, automatic feeding and low scrap rate.

Then set the cutting data. Finally put the honeycomb aluminium core into the instrument.

Where To Buy Aluminum Honeycomb Core?

WORTHWILL is not only honeycomb core manufacturer, but also a supplier. We provide a wide range of aluminum core includes 3003, 5052 series etc. And we also produce four types aluminum honeycomb panels include PETG, acrylic, stone grain coated and wood grain transfer. It’s available in a large range of configurations, which provide versatility for your specific needs.

Our Advantages

- Support customize: We can customize different densities, size and thickness according to customer requirements.

- Strict quality control: Products from our company have passed the domestic quality system certification.

- Factory cost price: We can provide you factory price. The price is competitive in the market.

- Experienced technical staff: Whether it is a business team or a technical team, they both have a wealth of work experience.

- Comprehensive service: Pre-sales and after-sales systems are complete in our company.