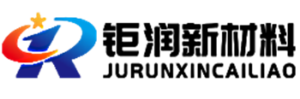

Aluminium Honeycomb Panel

- Home

- Aluminium Honeycomb Panel

Aluminium honeycomb panel is a composite material with aluminium honeycomb core sandwiched between two layers of aluminum panels. The alumiinum honeycomb core consists of many small honeycomb-like structures, similar to the shape of a beehive, hence the name. Aluminum honeycomb panels usually have the advantages of high strength, light weight, corrosion resistance, fire prevention, sound insulation, heat preservation, etc., and are widely used in construction, transportation, aerospace and other fields.

Specification

Name | Alloy | Width | Length | Thickness | Technology |

Aluminium honeycomb panel | Series1/3 | 1220-1500mm | 2440-3200 mm | 7-25mm | Film and roll coating |

*Customized according to customer requirements.

Feature

- Easy installation

- Light weight

- High strength

- Heat preservation

- Antibacterial

- Fire, moisture

- Corrosion resistance

- Decoration is easy to process

Application

- Interior decoration engineering

- Building curtain wall hanging board

- Advertising board

- Ship building

- Aviation industry

- Indoor partition

- Commodity display stand

Processing line

1.Aluminum plate cutting: the aluminum plate of the raw material is cut to the required size according to the requirements.

2.Surface treatment: Surface treatment of aluminum plate, such as decontamination, removal of oxidation layer, etc.

3.Coating treatment: The surface of the aluminum plate is coated with a layer of adhesive.

4.Aluminum honeycomb core sandwich: The aluminum honeycomb core is sandwiched with two coated aluminum sheets and pressurized to make it tightly bonded.

5.Cutting: The finished aluminum honeycomb panel is cut to the required size.

6.Inspection: The aluminum honeycomb panel is inspected to ensure that its quality meets the requirements

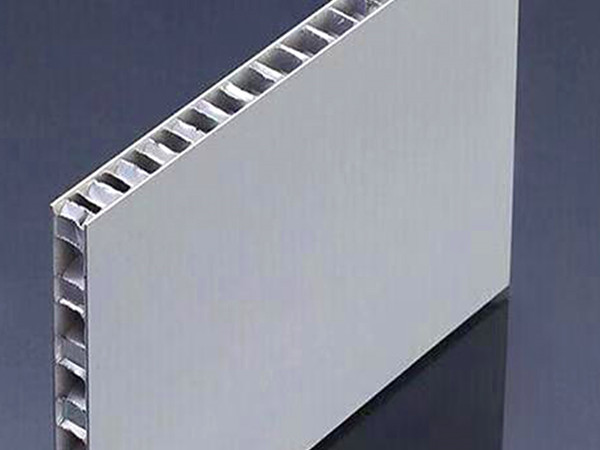

Honeycomb Core Sandwich Panels

Alloy: 3003 aluminum honeycomb core

Thickness aluminum foil: 0.04~0.06mm

Length: 5~6mm

Technology: roller forming

Honeycomb core sandwich panels offer higher strength-to-weight ratios than solid composite laminates. Using hot pressing technology, due to the high heat conduction value between the aluminum skin and the honeycomb, the thermal expansion and contraction of the inner and outer aluminum skin are synchronized. There are small holes in the honeycomb aluminum skin, so that the gas in the plate can flow freely. As well as the thermal expansion and contraction will not cause structural deformation, so it can ensure a very high flatness.

Surface

According to customer requirements for color painting, drawing, mirror, processing.

Temperature resistance

- Heat-pressed sheet : 150℃

- Cold-pressed sheet : 180℃

Package

International export standard package: bundled wooden box, suit for all kinds of transport

or according to the customers required.

Why choose us

Henan Worthwill Industry Co., Ltd is the international sales company of Henan Jurun New Material Co., Ltd. Our Factory is located in the Industrial Park of Huiguo Town, Gongyi, Zhengzhou, China, which is nearby Gongyi Nan High Speed Railway Station and G310 State Road with a convenient transportation.

Our company covers an area of 80,000 square meters with more than 200 employees, including more than 30 technical and management personnel. Our main products are aluminum color coating sheet/coil, curtain wall panel, wooden grain and marble coated products. We are the only one who can produce thickness 5.0mm and width 1800mm roller coated products in our province. We have 3 coating production lines in our plant with the thickness from 0.2mm – 5.0mm with max width 1800mm, we also have slitting machine, embossing machine, brushing machine and cutting machine.

Our serves:

- Provide free samples for your reference

- Reply to your message within 12 hours

- Professionals answer your questions

- Passionate business team

If you are interested in our products, please contact us in time and we will do our best to help you buy the products you need!