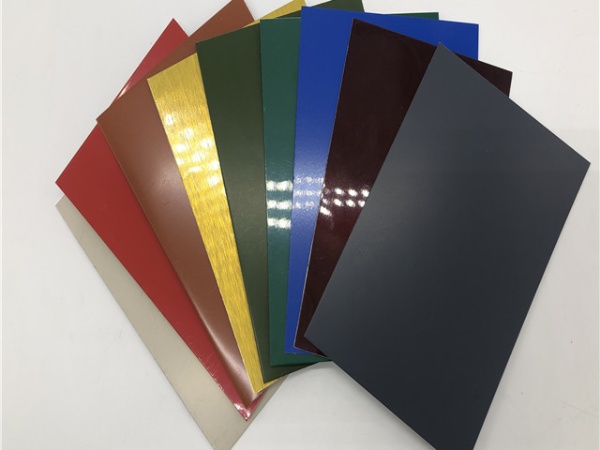

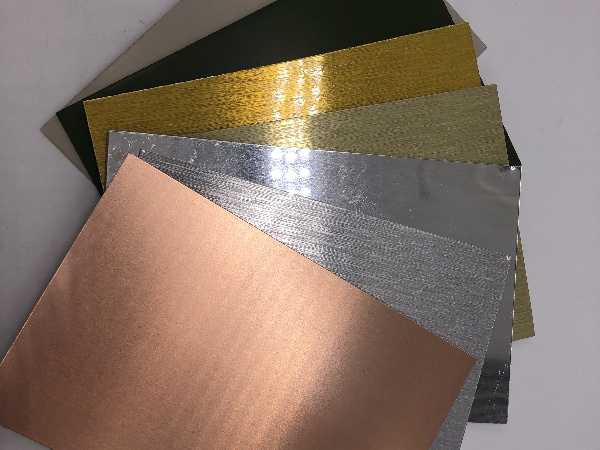

Painting aluminum coils is the surface coating of aluminum coil coloring treatment. The common ones are fluorocarbon coating (PVDF) and polyester coating (PE), which have stable performance and are not easy to corrosion. After special treatment, the surface quality can be guaranteed for 30 years. The weight per unit volume is lighter than that of metal materials. Color coating is a new type of building decoration material.

Specification of painting aluminum coil

| Alloy | 1050、1100、3003、3105、5005、5052 |

| thickness | 0.2-1.2mm |

| width | 600-2600mm |

| coating | PE PVDF |

| Coating thickness | PE>18um, PVDF>25um, back side:8-10um |

| application | Construction、 indoor decorations、 car manufacturer、 electronics,etc. |

Benefits of painting aluminum coil

- Aesthetic Appeal: Painted aluminum coil provides a wide range of color options, allowing for customization and design flexibility.So it enables architects, designers, and manufacturers to create visually appealing products and structures.

- Durability: The combination of aluminum’s inherent strength and the protective paint coating makes painted aluminum coil highly durable. Itnot only can withstand mechanical stresses, impacts, and abrasion, but also can reduce the risk of surface damage. The durability of painted aluminum coil ensures longevity and minimizes the need for frequent maintenance or replacement.

- Lightweight: Even in painting coated, Aluminum is a lightweight material.Therefore painted aluminum coil offers a high strength-to-weight ratio, making it advantageous for applications where weight reduction is crucial, such as in transportation or when constructing lightweight structures.

- Energy Efficiency: Painted aluminum coil can contribute to energy efficiency in various ways. The light-colored or reflective coatings used on the aluminum surface can help to reduce heat absorption, keeping the coated material cooler. This can be beneficial for buildings, vehicles, or appliances, leading to lower energy consumption for cooling purposes.

- Sustainability: Recycling aluminum requires significantly less energy compared to primary production, therefore make painted aluminum coil an environmentally friendly choice.

- Versatility: This versatility allows for its use in various fabrication processes, including roll forming, stamping, and bending. It is easy to integrate into different products and applications, offering design flexibility and ease of manufacturing.

Application of painting aluminum coil

Painting aluminum coil finds applications in various industries, including construction, automotive, aerospace, electronics, and signage. In construction, widely used in architectural cladding, roofing, and facade systems. In the automotive industry, painted aluminum coils commonly used for body panels and trim components. They can be employed in manufacturing consumer goods, appliances, and other products where a lightweight, durable, and aesthetically pleasing material is required.

Why to choose us?

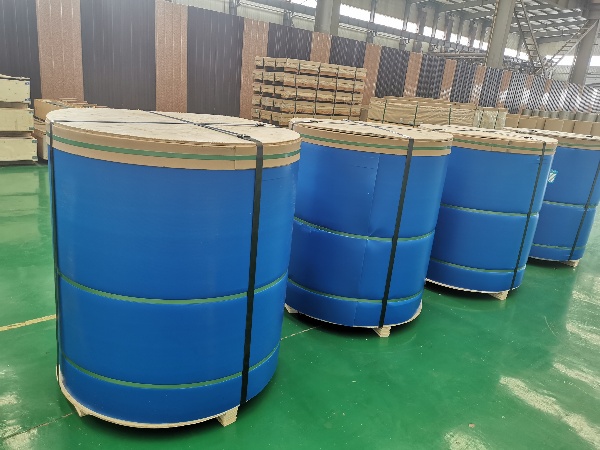

- processing line: Our factory has a completed production line and machine. For example, the direct casting processing line,continue casting processing line and color coated aluminum processing line.

- Competitive price: Wehave own factory. Therefore, we can offer you the factory cost price.

- Comprehensive products: wespecialize in aluminum products supplying for over 8 years; good quality and professional service help us gain many good reputation all over the world. Color coated aluminum rank1 in export market in our province.

- Fast delivery: We arrange shipment within 3 working days after confirming payment.

- Professional service: We supply 7*24hours professionals service for a client. From pr-sales, in-sales, after-sales, order details, arranging production, shipping packages.