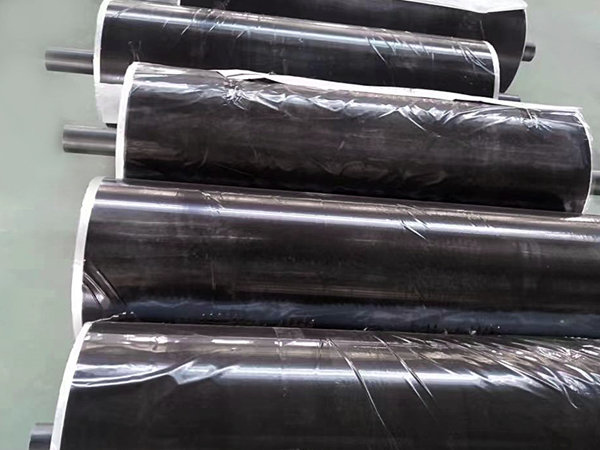

PE Protective Film

- Home

- PE Protective Film

PE protective film is the most widely used polymer material in the world today. It can protect the surface of the product during production, transportation, storage, use, etc.

Classification

Protective films canhas different types into black and white arrow protective film, transparent arrow film without words, transparent film without arrows, etc. We can also customize protective films according to customer requirements.

Advantage

- Rust-proof. It can effectively prevent rust and corrosion of metal products.

- Moisture-proof. Using it for sealed packaging can give full play to the moisture-proof advantages of PE protective film.

- Environmental protection. It can be recycled after use, which helps to reduce waste of resources and reduce pollution to the environment

- Scratch resistant and fingerprint resistant. Scratch resistance and fingerprint resistance are the two most important aspects of the protective film.

- High temperature resistance. It can withstand high temperature within 60°.

Application

Ultra-low viscosity protective film: organic plates, instruments, display screens, glass lenses, plastic lenses, etc.

Low viscosity protective film: mirror board, smooth plastic board, screen printing, nameplate, etc.

Medium and low viscosity protective film: metal plate, tile, marble, artificial stone, etc.

Medium viscosity protective film: fine grain frosted board, generally difficult to stick material.

High viscosity protective film: Aluminum plastic panel, difficult to stick plastic sheet, etc.

Ultra-high viscosity protective film: coarse grain aluminum plate and other difficult to stick materials.

What is PE protective film?

The full name of PE is Polyethylene, which is the simplest polymer organic compound in structure. PE protective film takes special polyethylene (PE) plastic film as the substrate, and is divided into high density polyethylene protective film, medium density polyethylene and low density polyethylene according to different densities.

Waste disposal method

The protective filmhas wide application in various fields, however, in the process of using protective film, it will inevitably produce a lot of waste. So what to do with all this waste? The methods mainly include the following:

- Recycling: The discarded PE protective film is recycled, and after cleaning, crushing, melting and other processes, it is re-made into a new protective film or other plastic products. This method can reduce the consumption of natural resources and reduce environmental pollution.

- Incineration treatment: The waste protective film is incinerated, and the heat generated can be used for power generation or other industrial production processes. However, incineration will produce a large amount of carbon dioxide and other harmful gases, which will have a certain impact on the environment.

- Landfill treatment: The waste PE protective film is landfill treatment, which can reduce pollution to the environment. However, landfill treatment takes up a large amount of land resources and may cause contamination of soil and groundwater.

Differences between PE protective film and PET protective film

PE protective film is a packaging film with comprehensive performance.It has good transparency and gloss; it has excellent sealing and fragrance retention properties. It has good waterproof properties and can reduce the moisture permeability at ultra-low temperatures. Therefore, it is often used to protect the surface of products from damage during manufacturing, transportation, and storage.

PET protective film has excellent mechanical properties, and its strong ductility, tensile strength and impact strength are much higher than those of ordinary plastic films. It is mainly used to produce mobile phone LCD protective films, LCD TV protective films, mobile phone keyboards, etc.

Why choose us?

- We have our own factory with a full range of products and can offer competitive price.

- We have the most advanced protective film production line equipment in China.

- We support customization and can produce protective films with various patterns.

- We have a strong production capacity of 6000 tons a year.

- We have an experienced team that can solve your problems.

- Our products comply with international standards.