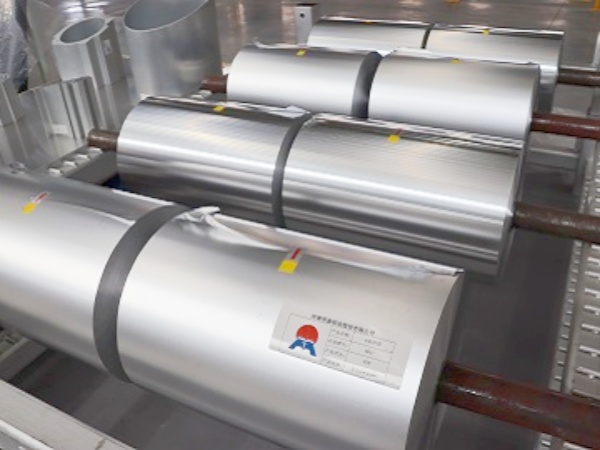

Pharmaceutical Aluminum Foil

- Home

- Pharmaceutical Aluminum Foil

Pharmaceutical aluminum foil currently has a wide range of applications. It has the advantages of non-toxic, corrosion-resistant, impermeable, heat-resistant, moisture-proof, light-blocking, and high-temperature sterilizability. Therefore, its uses include blister packaging of pharmaceutical capsules and tablets, and bag packaging of powder granules and liquids. In particular, PTP aluminum foil is moisture-proof, easy to carry, safe and hygienic. It is widely used in the international pharmaceutical industry.

Parameters

| Pharmaceutical aluminum foil | Temper | Thickness(mm) | Width(mm) | Application | Typical use products |

| 8011 | O, H18 | 0.016-0.5 | 100-1700 | PTP pharmaceutical aluminum foil | Capsule drug cover |

| 8021 | O | 0.04-0.065 | 100-1700 | Blister medicinal aluminum foil | Blister packs |

| 8021, 8079 | O | 0.016-0.2 | 100-1700 | Tropical pharmaceutical aluminum foil | High-end pharmaceutical packaging |

| 8011 | H14, H16 | 0.016-0.5 | 100-1700 | Aluminum foil for the cap | Aluminum-plastic composite caps for oral liquids and aluminum-plastic caps for infusion bottles |

The classification of pharmaceutical aluminum foil

There are two common classifications of pharmaceutical aluminum foil. That is 8011 medicinal foil and 8021 medicinal foil.

8011 pharmaceutical aluminum foil

Introduction: 8011 aluminum foil plate is added with Al-Fe-Si element. Among them, alloys with more than 1% of total alloy elements have correspondingly higher advantages. Processable range thickness: 0.02 mm-0.07 mm, width 300 mm-1100 mm, which can be customized according to customer needs.

Application: Mainly used for food packaging and pharmaceutical packaging.

We have a strong production capacity, with an annual production capacity of 650,000 tons of aluminum sheets, strips, and foils, and we provide long-term supplies to many companies around the world.

8021 pharmaceutical aluminum foil

Introduction: 8021 aluminum foil is one of the key products of our company. The thickness range of production is 0.018 mm-0.2 mm. The width can be controlled between 100-1650mm according to customer requirements.

Application: 8021 aluminum foil is the main product for food packaging and battery soft packaging aluminum foil.

Advantage: 8021 aluminum foil has excellent moisture-proof properties, light-shielding, and extremely high barrier capabilities. Non-toxic, tasteless, safe and hygienic. Aluminum foil after lamination, printing, and gluing is widely used as packaging material.

Application

- Pharmaceutical lids

- Pharmaceutical packaging

- Capsule plates

- Aluminum-plastic aluminum

Exported countries

Our products are global. We welcome any country to come to us for consultation. We used to export to many countries as well. Here are some of the successful exporting countries.

- India.

- Pakistan.

- Bangladesh.

- Vietnam.

- Tanzania.

- UAE.

Why choose our products?

Generally speaking, the main production process is about below

- billet inspection

- billet rolling

- open and middle-rolling

- coil rolling

- rolling finished products

- slitting

- furnace annealing

- finished product packaging

The surface of it requires no oil stains, no black lines, no cavities, no yellow spots, and no ruffles.

The control of surface and performance is the following points

First, we must control the quality of the source and strictly inspect the blanks.

Rolling. The control of surface quality is controlled by the following aspects. Cleaning of rolls, selection of rolling oil, reduction of rolling oil viscosity, and control of machine running speed.

Slitting. It is necessary to ensure that the edge of the aluminum coil is neat when slitting. There can be no quality problems such as wrinkles.

Annealing. The annealing time and annealing temperature are according to the performance requirements of the foil. Make sure the degreasing is clean.

With the development of the pharmaceutical industry, the proportion of pharmaceutical aluminum foil is rising. It has excellent moisture resistance, barrier properties, chemical resistance, chemical stability, and hygiene.

If you have a need, please contact us!