Protective Film

- Home

- Protective Film

Protective film has many advantages. Its biggest advantage is protecting the surface of the product. Keep it free from contamination, corrosion, and scratches during production, processing, transportation, storage, and use. It protects the original smooth and shiny surface. Thereby improving product quality and market competitiveness.

Types of PE Protective Film

The types of PE protective film has many kinds.

Such as blue, black, and white arrow protective film. Transparent wordless arrow film, a transparent film without arrows, and customer-specified protective film.

Application

1. Hardware industry: computer casing, galvanized sheet stamping, aluminum plate, stainless steel plate, titanium plate, plastic steel plate, glass plate, solar panel, etc.

2. Optoelectronic industry: LCD liquid crystal display, backlight panel, cold light film, membrane switch, mobile phone screen, etc.

3. Plastic industry: ABS, PP injection molded products, PVC sheets, acrylic sheets, instruments, plastic lenses, surface protection of spray-painted parts, etc.

4. Printing industry: PVC, PC board, aluminum plate, film, and other printing nameplate surface protection, etc.

5. Wire and cable industry: The protection of shaft-mounted copper wires, semi-finished products, finished products, and rolled finished products can effectively prevent dust pollution, and has anti-oxidation and anti-fouling effects.

6. In the electronics industry: during production, finished products and semi-finished products are generally protected from scratches and damage on the assembly line!

7. In the mobile phone digital industry: mobile phone film is also called mobile phone beauty film and mobile phone protective film. It is a cold surface film that can be used to install the body and screen of mobile phones.

Advantage

1. Suitable stickiness: easy to stick and easy to tear.

2. Stable peeling force: small change over time, that is, the smaller the increase in peeling force, the better.

3. Good weather resistance: under sunlight exposure conditions, the service life is as long as half a year to one year.

4. Long storage period: stored in the warehouse for more than one year, the quality will not change.

5. No pollution or corrosion: The adhesive is inert and will not react chemically with the surface of the adhered material.

6. Excellent mechanical properties: tensile strength, elastic modulus, elongation, etc. that meet user requirements.

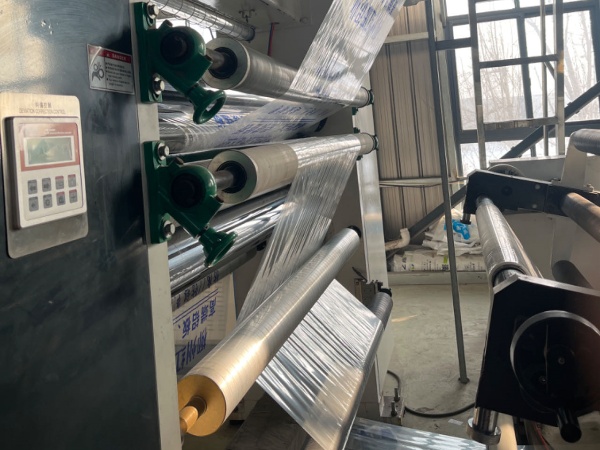

Processing line about PE protective film

- Plastic particles.

- Base film, add masterbatch to change color.

- Printing is not less than 0.04mm, foreign trade is above 0.06mm, and export is 0.1mm. Two layers of film are glued together, one side is transparent, and the other side is printed with a logo or text information (color) double-layer coating.

- Glue. We make custom viscosities based on customer sample color, paint, gloss, and processing requirements.

- Drying.

- Cutting and packaging width within 1.6m.

Development and progress

Society is developing and mankind is progressing.

People’s requirements for the quality of life are also constantly improving, and all kinds of new things are constantly appearing. Even though it seems ordinary, it also brings great convenience to our lives.

There have been problems in the packaging and transportation of some products in the past.

In the past, many of our products often had problems during transportation. The most common problem is wear and tear, which causes huge economic losses. Because once some items are worn out, they are useless.

In traditional packaging, our food industry and medical industry use a very large amount. The use of packaging in the past caused great environmental pollution.

At the same time, the production process of PE protective film is constantly improving. And the scope of our use is also constantly increasing.

If you have a need, you can contact us, we will give you a quick reply.